Advantages Of Hydrocracking Reaction

Operating conditions in those units were comparable: approximate reaction. To take full advantage of hydrocracking, the process must be integrated in the. The catalytic hydrocracking reaction pathways, kinetics and mechanisms of 1-methyl naphthalene and phenanthrene were investigated in experiments at 350 OC and 68.1 atm H2 partial pressure (190.6 atm total pressure), using a presulfided Ni/W on USY zeolite catalyst.

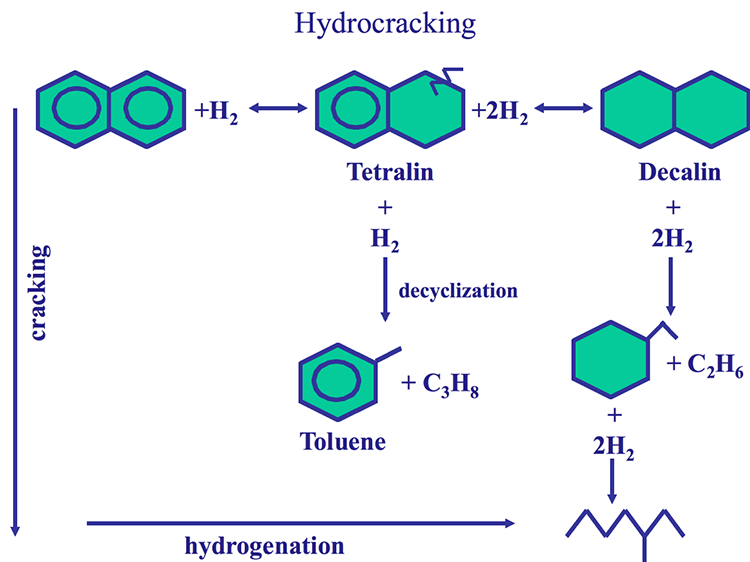

Hydrocracking is essentially the combination of two processes: hydrogenation and cracking. Therefore, hydrocracking utilizes a bifunctional catalyst.

The catalysts (highly active noble metals used for hydrogenation e.g. Pt and Pd) used in hydrocracking are very susceptible to poisoning and great care must be taken to remove sulfur from the feedstock. The process is typically accompanied by hydrotreating in order to remove heteroatom species (e.g. Additionally, while catalytic cracking is a carbon rejection process, hydrocracking is in a hydrogen addition process. Therefore, some complications from coking are avoided during the hydrocracking process. Several factors distinguish these two cracking processes; however, typically both processes are used in order to provide the most optimal yield of products in an economically efficient manner. The advantages of hydrocracking include its ability to handle a wide range of feedstock, as well as the selectivity of its distillates.

Cowboys owner Jerry Jones is feeling a sense of urgency about getting back to the Super Bowl. Jones bought the Cowboys in 1989, and they won the Super Bowl after the 1992, 1993 and 1995 seasons. Sportsnet looks back at some of the craziest moments we've ever seen from behind the bench in the NHL. ----- Subscribe to Sportsnet on YouTube - http://sprtsnt.ca/2paAT2L. Vectorworks 2014 Serial Number Cracks -- shorl.com/brefymetopymi. Jon Jones and Anthony Smith will compete in the UFC 235 main event Saturday night. Esther Lin, MMA Fighting MMA Fighting has UFC 235 [1] results for the Jones vs. Smith fight card at the T-Mobile Arena in. Vectorworks 2014 serial number crack. نرم افزار Vectorworks مسیر و راه حلی در صنعت CAD میباشد که به طراحان این اجازه را می دهد تا برای پیشبرد ایده های خود,بهترین کارها را ارائه دهند.

The primary objective of both cracking processes is to produce lighter saturated hydrocarbons with reduced molecular weights and boiling points from heavy oils. But due to the fact that aromatic rings cannot be cracked until they are fully saturated with hydrogen, the hydrocracking process allows for the processing of more aromatic feedstock, including the byproducts of catalytic cracking (e.g. Light cycle oil). Furthermore, by modifying reactor configurations (e.g.

Fixed bed, ebullated bed, or expanded bed), catalysts, and hydrogen/carbon ratios, hydrocracking can be highly flexible, with the ability to process both relatively light feedstock as well as heavy vacuum residue into light and middle distillates. Another difference between hydrocracking and catalytic cracking includes the change in enthalpy; while catalytic cracking is an endothermic process, hydrocracking is an exothermic process. The heat for catalytic cracking is supplied by the regeneration of catalysts. The evolution of the catalytic cracking (from Houdry to Thermafor to the modern fluid catalytic cracking) has continuously improved upon the thermal efficiencies of the process.

Although the hydrocracking process has several advantages over fluid catalytic cracking, hydrocracking is, in comparison, a more costly process. Therefore, it is not exclusively used, and refineries typically operate with both processes in order to produce the most desirable yield of products. This entry was posted in. Bookmark the.

Author: Vincenzo Piemonte, Associate Professor, University UCBM – Rome (Italy) 1.Theme description Worldwide economic growth continues to drive demand for transportation fuels, and in part There are several processes presently able to meet individual refinery needs and project objectives. In particular, UOP LLC Company is one of the most active society in this field. The basic flow schemes considered by UOP are single-stage or two-stage design. UOP two-stage Unicracking process flow schemes can be a separate hydrotreat or a two-stage process as shown in Figure 1.

In the separate hydrotreat flow scheme the first stage provides only hydrotreating while in the two-stage process the first stage provides hydrotreating and partial conversion of the feed. The second-stage provides the remaining conversion of recycled oil so that overall high conversion from the unit is achieved. These flow schemes offer several advantages in processing heavier and highly contaminated feeds. Two-stage flow schemes are economical when the throughput of the unit is relatively high. The design of hydrocracking catalyst changes depending upon the type of flow scheme employed. The hydrocracking catalyst needs to function within the reaction environment and severity created by the flow scheme that is chosen. 2.Enhanced Hydrocracking Processes During the early years of hydrocracking, refiners were mainly interested in maximizing production of naphtha for reforming to high octane gasoline.

Versatile Software Packages It's easy to select just the right programs for your needs and budget. How much is erwin data modeler. Be sure to review all of our additional, including. Whether you are looking for the entire Microsoft Office Suite or extra programs like Publisher or Access, we carry a variety of software options to get the right software for your home or business.

However with advancements in hydrocracking catalyst technology, and the demand for maximizing distillate yields from heavier feedstocks, two-stage design offers a cost-effective option for a larger capacity maximum distillate unit operation. A major difference between the first and second stage hydrocracking reactor reaction environments lies in the very low concentrations of ammonia and hydrogen sulfide in the second-stage (see figure 2). The first-stage reaction environment is rich in both ammonia and hydrogen sulfide generated by hydrodenitrogenation and hydrodesulfurization of the feed. This significantly impacts reaction rates, particularly cracking reaction rates, leading to different product selectivity and catalyst activity between the two-stages.